Virtual Training in Chemical

The chemical industry demands precision, preparation, and compliance. Employees work in high-stakes environments where mistakes can cause injuries, equipment damage, or regulatory violations. Standard training methods, such as classroom instruction or video demonstrations, often fall short of delivering the hands-on experience needed for effective learning.

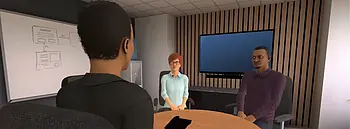

Virtual training in technology offers a better alternative. It allows your workforce to interact with lifelike simulations that mirror the hazards, equipment, and workflows of chemical facilities. These experiences are immersive, measurable, and tailored to real-world conditions.

Whether used for onboarding, upskilling, or safety reinforcement, virtual reality training solutions provide a risk-free platform to build confidence, accelerate knowledge transfer, and improve operational consistency. By reducing reliance on physical resources and increasing engagement, this approach helps chemical companies meet both safety and productivity goals.

Why Virtual Training Fits the Chemical Industry

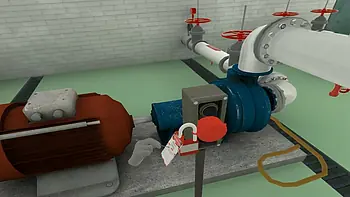

The nature of chemical operations makes virtual training not just useful, but necessary. Teams often work with volatile compounds, pressurized systems, and automated machinery. Mistakes during hands-on learning can be costly or dangerous. Virtual environments eliminate these risks while preserving the complexity of the task.

A couple of reasons virtual training in technology is ideal for chemical facilities include:

- Safety without compromise. Simulations allow employees to practice emergency shutdowns, chemical transfers, and incident response without risk.

- Scalable across locations. Train employees in different plants with the same scenarios, ensuring standardized learning company-wide.

- Adaptive to roles. Each course can be tailored to specific functions: technicians, lab staff, process engineers, or maintenance teams.

- Error-based learning. Trainees learn what happens when steps are skipped, or procedures fail, improving memory and retention.

- Real-time monitoring. Trainers can observe decision-making processes, helping them identify strengths and correct weaknesses quickly.

Key Applications of Virtual Training in Technology

Virtual training can be applied to nearly every area of the chemical workflow, from raw material handling to compliance inspections. These simulations are scenario-driven and job-specific, allowing employees to practice actual tasks in environments modeled after their own.

Hazardous Material Handling

- Identify storage protocols, labeling systems, and segregation rules.

- Train on procedures for receiving, storing, and moving dangerous chemicals.

- Respond to spills, leaks, and exposure incidents with predefined response plans.

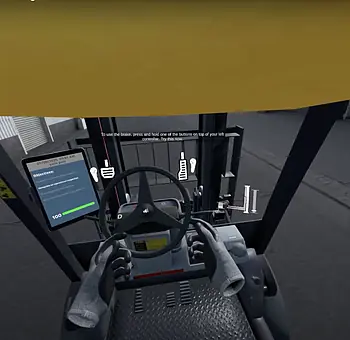

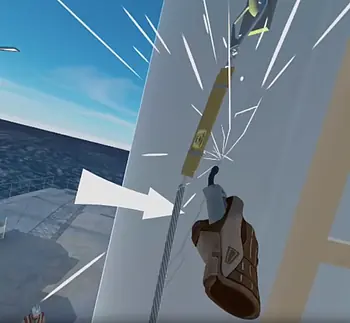

Process Equipment Operation

- Practice operating key systems such as mixers, reactors, distillation towers, or valves.

- Understand pressure dynamics, temperature control, and batch tracking using digital twins of real machines.

- Perform mock start-up and shutdown sequences.

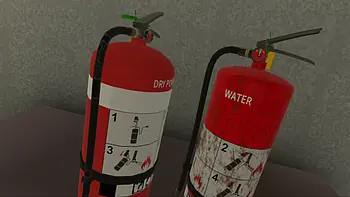

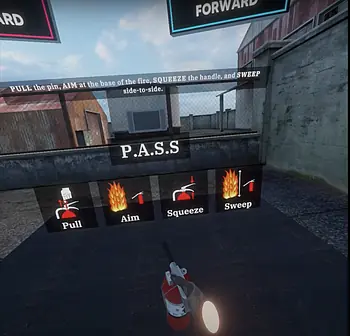

Emergency Response and Containment

- Simulate toxic vapor release, chemical fires, or system overpressures.

- Train on alarms, evacuation routes, and emergency communication.

- Practice isolating equipment, sealing leaks, and coordinating with response teams.

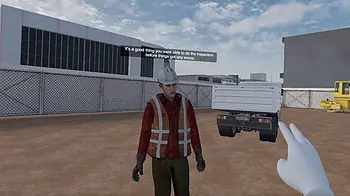

Quality Control and Inspection

- Rehearse visual inspections and testing protocols.

- Identify contamination, incorrect labeling, or procedural deviations.

- Record findings using virtual checklists tied to company SOPs.

Environmental and Regulatory Compliance

- Reinforce compliance with GHS, OSHA, EPA, or international guidelines.

- Simulate environmental incident reporting and documentation.

- Train staff on safe waste disposal, emission tracking, and auditing procedures.

Such applications show that virtual reality training solutions are not limited to one function. They can support an entire safety and productivity ecosystem.

Advantages of Virtual Reality Training Solutions in the Chemical Sector

The chemical industry faces growing complexity, from new technologies to tightening regulatory expectations. Virtual training solutions help organizations meet these challenges through consistent, scalable education that builds real-world skills.

- Increased engagement. Employees focus more when they solve problems or make decisions in a virtual space that replicates their daily tasks.

- Reduced onboarding time. New hires reach operational readiness faster through immersive repetition and task-based progression.

- Lower risk. Training no longer exposes people or equipment to unnecessary hazards.

- Cross-functional flexibility. Create different scenarios for maintenance crews, safety teams, operators, and quality control personnel.

- Faster adaptation to change. Update procedures, policies, or layouts virtually and roll out updates instantly.

- Evidence of performance. Capture detailed learner data to support audits, compliance checks, or retraining initiatives.

Virtual technology training helps chemical manufacturers build a more agile, responsive workforce while maintaining control over safety and quality.

Implementing Virtual Training for the Chemical Industry

A successful training system requires planning, customization, and feedback. These steps will help chemical manufacturers effectively roll out virtual programs.

Step 1: Identify Training Needs and Safety Priorities

Start with a risk-based approach. Review past incidents, audit findings, and near-misses to determine which processes need better training.

- Where do knowledge gaps exist?

- Which tasks present the highest operational risk?

- What changes are coming that may require retraining?

Prioritize simulations that address these concerns first.

Step 2: Set Measurable Objectives

Each course should be tied to a specific performance metric.

- Reduce errors in the manual handling of chemicals.

- Improve shutdown response time.

- Increase compliance reporting accuracy.

With clearly defined outcomes, both learners and managers know what success looks like.

Step 3: Choose the Right Format

Not all scenarios require full VR. Options include:

- 3D desktop simulations. Best for quick access and broad rollout.

- VR headset-based immersion. Ideal for high-risk, hands-on procedures.

- Mobile access. Good for basic refreshers or compliance reviews.

Select formats based on employee roles, training goals, and available infrastructure.

Step 4: Reflect Your Environment

Use 3D models, facility layouts, and real equipment specifications. The more familiar the environment, the better the learning experience.

- Customize PPE, signage, and workflows.

- Match equipment controls to those used on-site.

- Recreate standard operating conditions and likely failure points.

Step 5: Monitor, Analyze, and Improve

- After deployment, track usage, completion, and assessment scores.

- Adjust difficulty based on feedback.

- Add optional challenges for experienced staff.

- Use dashboards to track team-wide progress.

With consistent monitoring, your training evolves with your operations.

Extending the Value of Training Across the Organization

Virtual training should not be limited to frontline operators. Its benefits extend across departments and job levels:

- Management. Train supervisors on team coordination during emergencies or compliance audits.

- R&D. Prepare scientists for lab safety, experimentation protocols, and material handling.

- Maintenance. Reinforce shutdown procedures and hazardous equipment repair safety.

- Contractors. Quickly onboard short-term workers without risking production errors.

Organizations create a culture of shared responsibility and continuous improvement by building a training strategy that includes all stakeholders.

Measuring Training Impact and Continuous Improvement

Implementing virtual training is only part of the strategy. To achieve lasting value, organizations must track how training influences real-world performance and use that data to refine content and delivery, ensuring your investment delivers measurable outcomes aligned with operational goals.

Begin by establishing baseline performance metrics before deployment. These might include error rates, incident frequency, audit outcomes, or time-to-competency for new hires. After introducing virtual training, similar benchmarks will be compared over time to identify areas of improvement.

Many virtual training platforms offer built-in analytics to capture:

- Task completion times. Helps determine how efficiently employees execute steps after repeated training.

- Error trends. Identifies where mistakes are common and where instruction may need reinforcement.

- Decision pathways. Tracks how users navigate scenarios, including correct and incorrect actions.

- Retention assessments. Measures how well employees recall protocols after intervals of time.

Managerial feedback should also be part of the loop. Supervisors can observe behavioral changes, such as improved safety awareness, faster response to equipment issues, or increased procedural accuracy.

Based on this data, companies can update simulations to reflect new procedures, add advanced scenarios for experienced employees, or simplify overly complex tasks. In high-risk environments like chemical manufacturing, adapting and improving training over time is critical. A data-driven approach ensures your virtual training program evolves alongside your workforce and technology.

A Safer, Smarter Way to Train

Proper training is non-negotiable in the chemical industry. Lives, assets, and reputations are on the line every day. Virtual reality training solutions allow companies to prepare employees for this reality without exposing them to the consequences of mistakes.

By investing in virtual technology training, you not only future-proof your operations but also build a team capable of responding confidently and consistently. You replace static lessons with dynamic engagement and memorization with mastery. Employees should not complete the training once and forget it. They should experience, reflect on, and apply it every day. Virtual training makes this possible.

Found 39 results