Virtual Training in Telecom

Telecom companies face constant pressure to expand infrastructure, maintain uptime, and respond to technology shifts without compromising safety or quality. From tower work to customer installations, the industry depends on skilled technicians who can perform accurately in the field.

Yet training often falls short. Many teams rely on inconsistent instruction, outdated materials, or limited access to physical assets. Virtual reality training solutions solve that problem by replicating real telecom environments through simulation. Workers develop technical and safety skills through active experience.

Why Traditional Telecom Training Falls Short

Telecom fieldwork is complex. Each technician must follow specific steps, often in unfamiliar conditions, with no room for error. But conventional training rarely prepares teams for those demands.

In many cases, new hires receive a stack of PDFs, sit through classroom slides, or shadow someone briefly before being sent into the field. Equipment updates arrive before training does. Safety practices are delivered in generic formats that don't match actual job sites.

The result is predictable: longer task times, uneven service quality, and a spike in early-stage mistakes. Simulation-based training replaces that with structured, scenario-driven preparation.

What Simulation Brings to Telecom

Unlike general e-learning tools, simulation platforms are built to reflect actual telecom hardware, environments, and procedures. Trainees see what they will work with. Everyone gets time to repeat, correct, and refine their skills before the first work order lands.

Preparing Teams Before They Reach the Site

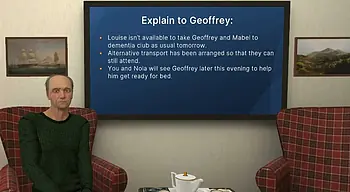

Live telecom sites are often unfamiliar, constrained, or remote. Work delays happen when technicians spend their first hour just figuring out the layout, equipment access, or anchor points. Virtual training solves that through advanced walkthroughs.

Staff explore exact layouts digitally, learn how to enter safely, identify gear locations, and review known hazards. That familiarity shortens setup times, reduces confusion, and increases the likelihood of finishing the job on the first visit.

Safety Without the Risk

Not every risk can be trained for in a live setting. Arc flash, confined space access, electrical faults, and tower rescue protocols are difficult or dangerous to simulate physically.

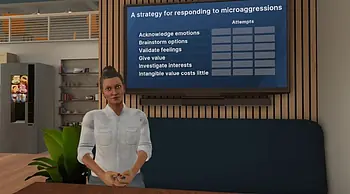

Simulation makes it possible. Trainees experience controlled emergencies that unfold based on their choices. They fail, recover, repeat. With each attempt, they understand what decisions lead to safety violations and what actions prevent them. Such an approach creates habits before anyone steps near a real hazard. Reaction time improves. Judgment becomes faster.

One Platform for All Roles

Telecom teams include more than just tower climbers. Line testers, fiber techs, equipment installers, and customer support engineers each need role-specific knowledge. Simulation allows all of that to be delivered through the same platform without one group slowing down another.

Scenarios are modular. Each team member can follow their own track, using the same interface and scoring system. Everyone gets what they need at the pace that fits their role.

Internal Coordination That Works

New procedures and hardware rollouts are often held back by delayed training cycles. Documentation takes time to update. Field instruction depends on local trainers being available.

With simulation, changes can be introduced as soon as they're finalized. Need to train teams on a new connector type or signal test method? The digital environment can be updated in days and available across all teams instantly. Fewer delays mean faster rollouts, fewer incorrect installations, and less pressure on support lines to resolve avoidable errors.

Assessment Built Into the Process

It's hard to evaluate technical performance using multiple-choice quizzes or attendance records. Simulation training changes that by embedding measurement directly into each session. Managers can review heat maps of errors, see who struggled with what, and assign retraining if needed, which gives leadership a factual basis for promotion decisions, project assignments, and risk assessments.

Where Costs Drop Without Cutting Quality

Live instruction drains resources. Each in-person session requires time, gear, space, and coordination. When new equipment is used for training, that equipment isn't available for live projects. The more people that need onboarding, the harder it gets to scale efficiently. Simulation eliminates most of that burden. Once a scenario is created, it can be reused thousands of times. Training becomes predictable in cost, outcome, and availability.

Real-World Scenarios Trained in Simulation

Below are just a few of the tasks telecom teams can train for inside a virtual environment:

- Climbing and anchoring on rooftop or tower setups;

- Fiber splicing, polishing, and connector testing in varied conditions;

- Equipment grounding and electrical diagnostics in tight enclosures;

- Signal troubleshooting using live-data simulations;

- Lockout/tagout procedures before servicing power equipment;

- Emergency descent and fall arrest testing during tower incidents.

Each session mirrors the same tools and conditions found in real work orders.

What Virtual Training Improves

Virtual training in technology improves telecom operations in direct, measurable ways. The changes aren't theoretical. They're built into how jobs are done, how safety is handled, and how teams perform under pressure.

- Reduced time to onboard and deploy new hires;

- More consistent performance across locations and roles;

- Fewer mistakes made during high-risk tasks;

- Faster adoption of new equipment and standards;

- Stronger retention of procedures due to active repetition.

Every completed simulation leads to faster task times and fewer errors in the field.

Supporting Large-Scale Projects Without Training Bottlenecks

Telecom projects often scale fast. Regional expansions, infrastructure upgrades, and technology rollouts require dozens or hundreds of technicians to be brought up to speed within tight timeframes. Traditional training structures rarely keep up. Scheduling issues, limited instructor availability, and bottlenecks around equipment access delay deployment and create uneven results.

Simulation solves that by removing dependency on location or physical assets. Once a new process or configuration is approved, it can be modeled, tested, and distributed to all relevant teams within a few days. Employees don't have to wait for a trainer, attend a specific location, or coordinate around shared gear. They simply log into the system and begin.

As a result, large-scale projects no longer need to be delayed by logistical training constraints. If 200 technicians need to learn how to install a new type of outdoor enclosure, every one of them can complete that training in the same week, regardless of site or shift. That allows deployment teams to move faster, with fewer delays caused by uneven preparation.

With simulation-based instruction, large rollouts gain alignment early. Managers don't spend hours checking whether staff have seen the latest updates. Instead, they track completion and performance through centralized data. Field performance improves, repeat work declines, and training shifts from a point of friction to a force multiplier that enables project success under pressure.

Reducing Field Support Calls Through Better Preparedness

Support teams inside telecom companies often carry the burden of incomplete training. When field staff enter jobs without proper hands-on practice, they make more calls for help, escalate more tickets, and consume limited engineering time. Most of those calls could be avoided with more targeted and realistic preparation before dispatch.

Simulation reduces support volume by giving field technicians a chance to practice failure conditions and recovery procedures in advance. Instead of encountering unfamiliar alerts or equipment quirks on-site, they already know what those conditions look like and what to do next. That knowledge prevents unnecessary service tickets and stops avoidable downtime from spiraling into multi-person troubleshooting sessions.

Even small improvements in technician readiness create measurable relief for support teams. A reduction in call-ins during fiber configuration, for example, frees engineers to focus on more complex issues. The difference compounds quickly. Support teams don't waste time walking someone through basic errors, and field teams don't waste time waiting for answers that should have been covered earlier.

In addition, support staff can use simulation themselves to stay current. When a new product or configuration is introduced, they can experience it the same way as the field teams they assist. That creates shared context and makes communication more direct. Problems are solved faster, and everyone saves time.

Reducing field escalation doesn't require more policy. It requires better preparation. Simulation gives that preparation without increasing support load, and in doing so, actually reduces it over time.

Conclusion

Telecom networks only function well when the teams behind them perform with skill and consistency. Weak training undermines that. Delays, confusion, and preventable safety issues stem from inadequate staff preparation.

Virtual reality training solutions fix that at the source. With simulation, teams learn what they need, practice it fully, and repeat until they get it right. Training shifts from a bottleneck to a strength. The result is a workforce that shows up confident, capable, and ready to do the job right the first time.

Found 35 results