Virtual Simulations in Chemical

The chemical industry operates under constant pressure to strike a balance between safety, efficiency, and regulatory compliance. Complex processes, hazardous materials, and high-value equipment leave little margin for error. Traditional training or documentation cannot fully prepare teams for the urgency of live operations or the risks of experimental testing.

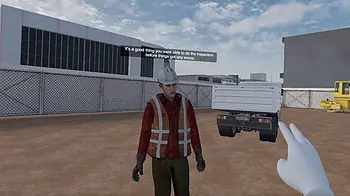

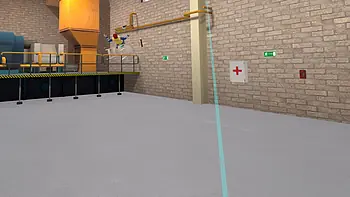

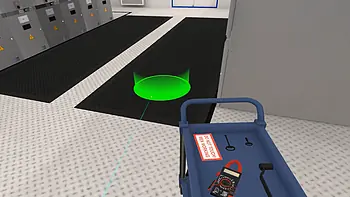

Virtual simulations provide the missing link. By modeling chemical processes, laboratory tasks, and safety-critical responses in controlled environments, organizations can evaluate procedures, optimize design, and prepare staff without exposing them to real-world hazards. Every participant interacts with a dynamic, role-specific scenario that mirrors the responsibilities, risks, and outcomes of actual chemical operations.

Challenges of Conventional Training and Testing

Many chemical companies rely on static manuals, safety posters, or occasional in-person demonstrations. While these resources are important, they fail to replicate the pace and complexity of chemical environments.

Some shortcomings include:

- Limited realism. Documentation cannot reproduce the urgency of a pressure rise, toxic release, or fire ignition.

- High costs of live trials. Pilot plants and experiments demand expensive equipment and consumables.

- Low frequency of drills. Infrequent training leads to poor retention and inconsistent readiness.

- Isolated preparation. Staff often understand their own role but lack insight into cross-department dependencies.

When errors occur, they can result in downtime, regulatory penalties, or significant safety incidents. Virtual simulation eliminates these risks by providing safe, repeatable conditions for preparation.

What Virtual Simulations Deliver for the Chemical Industry

Virtual simulations extend far beyond theoretical learning. They replicate full chemical processes with interactive logic, branching outcomes, and measurable feedback.

Key benefits include:

- Dynamic process simulation. Entire reaction pathways, distillation setups, or heat exchange systems can be modeled digitally.

- Digital twin applications. Live plant operations are mirrored in real-time, enabling predictive maintenance and optimization.

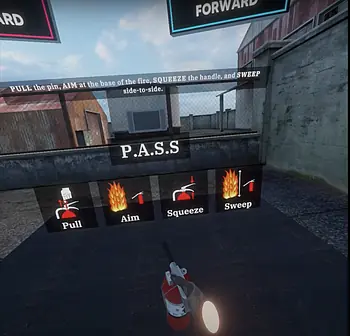

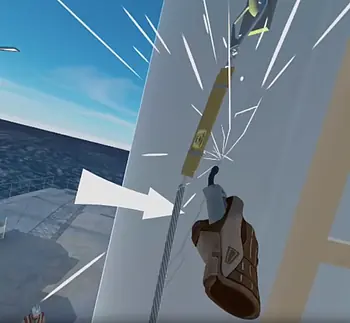

- Safety simulation. Workers rehearse emergency responses such as spill containment or confined-space evacuation.

- Virtual laboratory environments. Researchers test chemical reactions or workflows without using physical reagents.

- Data-rich assessment. Every decision is recorded and analyzed to identify strengths and gaps.

Simulation allows chemical companies to innovate, train, and operate with greater confidence and reduced exposure to risk.

Types of Simulated Scenarios in Chemical Operations

Virtual simulations can be tailored to reflect the specific hazards and workflows of chemical plants, laboratories, and supply chains.

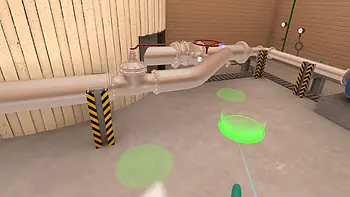

Common scenarios include:

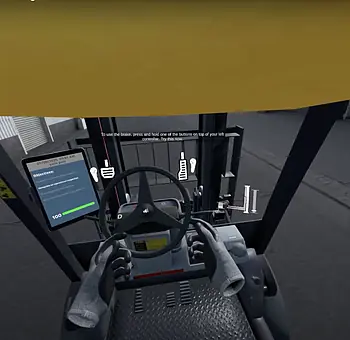

- Reactor startup and shutdown procedures.

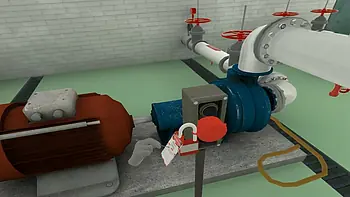

- Lockout-tagout processes for energy isolation.

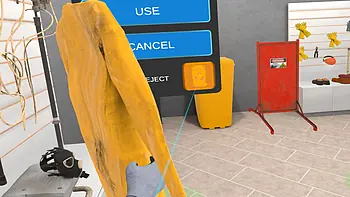

- Handling of hazardous material spills and leaks.

- Distillation and separation optimization studies.

- Fire suppression training in flammable environments.

- Confined-space entry with gas monitoring.

- Scale-up simulations for pilot-to-plant transitions.

Each scenario is configured to match real equipment, plant layouts, and safety protocols, ensuring relevance and applicability.

Improving Safety Performance Through Simulation

Workplace accidents in the chemical sector often occur during rare but high-impact events, such as uncontrolled reactions, toxic gas releases, or equipment malfunctions. Conventional drills cannot reproduce these situations at scale or frequency.

Virtual simulations provide a safer and more effective method. Employees face evolving hazards, time pressure, and conflicting data. Managers observe how teams prioritize responses, coordinate communication, and adapt to changing conditions. Results are measurable and repeatable, enabling continual improvement of safety readiness.

Process Optimization Without Physical Risk

Designing or modifying chemical processes through physical experiments is expensive and time-intensive. Virtual modeling tools allow organizations to evaluate designs and optimize workflows before implementation. By adjusting variables such as feed rates, temperatures, or catalyst concentrations, engineers can test outcomes instantly. Digital twins further enhance this by integrating live operational data into simulations.

R&D Acceleration Through Virtual Laboratories

Research and development cycles in the chemical industry are traditionally long and resource heavy. Virtual simulation shortens timelines by enabling rapid experimentation in digital form. R&D teams can simulate chemical reactions, explore material properties, and refine formulations before moving to physical testing. This reduces waste, accelerates innovation, and lowers costs. By using R&D simulation tools, organizations maintain a competitive edge while ensuring that experimental risks are managed effectively.

Benefits Across Organizational Levels

Virtual simulations in the chemical industry create advantages for operators, managers, and leadership alike:

- Operators. Gain hands-on experience with hazardous procedures in a safe environment.

- Supervisors. Observe staff performance, identify gaps, and reinforce protocols.

- Engineers. Validate designs and process changes virtually before live deployment.

- Leadership. Access measurable performance data to guide investment and compliance decisions.

Simulation integrates preparation, oversight, and strategic decision-making into a single framework.

Measurable Outcomes and Performance Tracking

Unlike conventional training, which often ends with attendance sheets or basic quizzes, virtual simulations provide detailed, behavior-based metrics.

Organizations can track:

- Decision accuracy under time pressure.

- Response time to escalating hazards.

- Adherence to process protocols.

- Communication and escalation effectiveness.

- Completion and repetition rates across staff.

These insights feed directly into performance management, compliance audits, and continuous improvement strategies.

Scaling Training Across Global Facilities

Chemical companies often operate across multiple plants, laboratories, and geographies. Standardizing training and safety readiness can be challenging.

Virtual simulations overcome these challenges by enabling:

- Consistent delivery of identical scenarios worldwide.

- Localization of language and plant-specific parameters.

- Remote access for distributed or shift-based teams.

- Uniform reporting for centralized oversight.

Every employee, regardless of location, receives the same preparation and assessment, ensuring a unified standard of readiness.

Supporting Compliance and Regulatory Requirements

The chemical sector faces rigorous oversight from regional and international regulatory bodies.

Virtual simulations help satisfy these requirements by:

- Providing documented logs of scenario participation.

- Recording performance outcomes for each participant.

- Linking scenarios to regulatory standards and internal SOPs.

- Offering version control for updated procedures.

Auditors and regulators receive verifiable evidence that staff are not only trained but also capable of performing under realistic conditions.

Long-Term Organizational Advantages

The adoption of virtual simulations creates lasting benefits beyond immediate safety or efficiency gains. Over time, organizations develop:

- Continuous readiness. Staff rehearse scenarios repeatedly, maintaining fluency over the years.

- Knowledge retention. Institutional expertise is preserved as simulations evolve with operations.

- Cost efficiency. Physical trials, resource consumption, and downtime decrease.

- Innovation culture. Experimentation becomes faster and safer, encouraging the development of new processes.

- Resilience. Companies adapt more quickly to regulatory changes, market shifts, or operational risks.

Virtual simulation evolves from a training tool into a strategic asset.

Implementing Virtual Simulations in Chemical Operations

Successful programs start with a narrow, high-impact use case and expand in planned phases. Leaders begin by selecting one process unit, one hazard profile, or one R&D workflow with clear KPIs such as reduced incident rate, faster scale-up, or lower energy consumption. Scope clarity prevents overdesign and delivers early proof that simulation affects safety, yield, or uptime.

Technology foundations matter. Engineering selects a process simulation stack that matches unit operations and thermodynamics libraries, then defines model fidelity by purpose: training scenarios favor clarity and branching logic, while optimization models require accurate kinetics, mass balance, and control loops. Digital twin integrations connect historian data, DCS tags, and maintenance systems so that users rehearse procedures against conditions that resemble the real plant.

Content production follows a structured pipeline. SMEs draft SOP-aligned flows, safety engineers translate hazards into triggers and interlocks, and instructional designers convert steps into interactive decision points. Visual accuracy improves adoption; however, realism must not come at the expense of performance on standard laptops. Review cycles validate that alarms, interlocks, and emergency procedures behave exactly as written in the management of change documentation.

Change management drives results. Supervisors schedule short, frequent sessions woven into toolbox talks, while HR assigns completion windows by role and shift. Analytics dashboards highlight skill gaps, late responses, or incorrect escalations so coaches can reinforce specific behaviors. Operators who complete a scenario receive targeted refreshers rather than repeating generic training.

Governance keeps programs sustainable. Version control records every revision to match updated SOPs, while access control limits sensitive scenarios to authorized roles. IT enforces data protection, and EHS maps each scenario to regulatory requirements and audit trails. Quarterly reviews expand coverage to additional units, introduce localized content for regional sites, and retire outdated models so the portfolio remains relevant and measurable.

The Bottom Line

The chemical industry is uniquely complex, with high-value processes and significant safety considerations. Relying on documentation and occasional drills leaves organizations vulnerable to accidents, inefficiencies, and delays.

Virtual simulations offer a comprehensive solution. By modeling processes, replicating hazardous conditions, and providing measurable feedback, companies can train employees, optimize workflows, accelerate R&D, and ensure compliance.

Every decision is tested, every process is validated, and every employee is prepared before real-world execution. Virtual simulations for the chemical industry transform operations from assumption-based to experience-based, creating safer workplaces and stronger business performance.

Found 30 results