Virtual Training in Oil and Gas

The oil and gas industry operates in some of the most hazardous and complex environments on the planet. From offshore platforms to high-pressure pipelines, employees work with volatile substances, sensitive machinery, and strict regulatory demands.

A single misstep can result in operational shutdowns, environmental damage, or severe injury. Despite this, many organizations still rely on outdated, instructor-led training methods or passive content that fail to prepare workers for high-risk situations adequately.

Virtual reality training solutions provide a modern, scalable, and practical approach to skill development across upstream, midstream, and downstream operations. By using immersive digital environments that simulate real-world tasks, teams gain hands-on readiness without the dangers or costs associated with live exercises.

Virtual training in technology helps reinforce operational procedures, safety compliance, and crisis response while aligning with the industry's productivity and risk mitigation goals.

Why Oil and Gas Training Needs an Upgrade

Conventional training methods struggle to address the realities of oil and gas operations:

- Remote and offshore locations limit access to live training environments.

- Live drills can be risky, especially in confined spaces, explosive atmospheres, or unstable weather conditions.

- New hires face steep learning curves, particularly on equipment that cannot be taken offline.

- Compliance requirements are strict, but tracking actual competency can be inconsistent.

- Emergency scenarios are challenging to rehearse in real time without putting personnel at risk.

Virtual training in technology removes these barriers. Teams can rehearse complex tasks, navigate hazardous conditions, and respond to simulated emergencies with complete control and repeatability. Each training session is realistic, structured, and measurable, with scenarios tailored to specific roles and environments across the oil and gas industry.

Simulation-Based Learning Across Operations

Virtual training supports a wide range of use cases in oil and gas, providing tailored solutions for different segments of the industry:

Upstream (Exploration and Production)

Trainees can rehearse rig operations, well control procedures, and drilling safety protocols in a virtual setup. Simulations cover blowout preventer (BOP) response, equipment inspections, fall protection, and emergency evacuations, all without interrupting active rigs.

Midstream (Transportation and Storage)

Operators practice pipeline monitoring, valve control, hazard identification, and containment protocols in simulated pipeline environments. Leak detection, pressure response, and emergency shutdown drills can be executed without field exposure.

Downstream (Refining and Distribution)

Personnel train on refinery workflows, flammable liquid handling, control room operations, and maintenance procedures. Virtual environments allow users to safely practice shutdown procedures, pump operation, and gas detection protocols.

These simulations can replicate extreme temperatures, high-pressure systems, gas leaks, and exposure to hazardous materials without putting anyone in harm's way.

Elevating Safety with Immersive Training

Safety remains the highest priority in oil and gas. Yet safety briefings, slide presentations, and occasional drills often fail to engage workers or simulate the true stress of high-risk events.

Virtual reality training solutions change this by placing the trainee inside the scenario. Instead of reading about fire response or watching a video on confined space entry, personnel must make decisions, take action, and see the consequences unfold in real time.

Key safety training scenarios include:

- Confined space entry procedures

- Fire suppression and evacuation

- Gas leak identification and isolation

- High-pressure system response

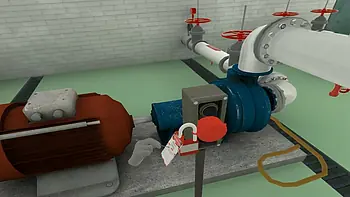

- Electrical lockout/tagout

- Helicopter landing zone (HLZ) coordination on offshore platforms

Each simulation reinforces physical behavior, decision-making, and compliance standards, preparing workers not only to follow protocols but to apply them under pressure.

Reducing Risk During Onboarding and Retraining

New hires often arrive with no direct exposure to the environments in which they'll work. Waiting until they step onto an active platform or terminal to begin hands-on training creates risk and slows productivity. Retraining veteran personnel presents similar challenges, especially when roles evolve or new systems are introduced.

Virtual training addresses this by providing a preparatory path that allows users to experience the equipment, workflows, and hazards of their future roles before they even leave orientation. Trainees learn procedures in safe, repeatable environments that replicate site-specific layouts and real tasks.

Benefits include:

- Faster onboarding timelines

- Lower exposure for inexperienced workers

- Reduced supervision requirements

- Higher skill retention during retraining

- Adaptation to new equipment or processes

As a result, companies see faster deployment readiness and fewer early-stage mistakes.

Consistency Across Locations and Job Roles

Oil and gas operations often span multiple regions, contractors, and facilities. Ensuring consistent training and compliance across this network is difficult using manual, on-site instruction alone. Different trainers may deliver the same content in slightly different ways, leading to inconsistencies in what workers understand and how they perform.

With virtual training in technology, each employee receives the exact same scenario, instructions, and assessment criteria. From offshore engineers to refinery technicians, all personnel can be trained to meet the same standards regardless of geographic or organizational differences.

This is especially valuable for:

- Global operations and joint ventures

- Contractor onboarding

- Third-party certification prep

- Language-independent learning

- Skill validation across rotating crews

Digital training environments ensure uniform instruction and universal performance expectations.

Enabling Crisis Response and Emergency Preparedness

Emergencies in the oil and gas industry can be catastrophic if personnel are unprepared. Yet, many of the most hazardous scenarios, such as explosions, equipment failures, and toxic gas releases, cannot be safely rehearsed using traditional methods.

Virtual reality training solutions allow companies to simulate these emergencies at full scale without putting people or equipment at risk. Workers learn to react to alarms, assess danger, follow evacuation paths, and coordinate responses under pressure.

Example crisis simulations include:

- Offshore platform fires

- High-pressure line ruptures

- Gas cloud dispersion

- H2S exposure response

- Rescue and recovery operations

These high-impact exercises create memorable training moments and help normalize responses under real-world stress conditions.

Lowering Cost While Increasing Training Impact

Live training in the oil and gas industry is costly. It requires specialized instructors, isolated facilities, and downtime on expensive infrastructure. Mistakes can result in material waste, equipment damage, or delays in operations.

Virtual training in technology removes many of these expenses. Once a simulation is developed, it can be reused across sites and teams with minimal incremental cost. Instructors spend less time repeating sessions, and trainees can progress independently at their own pace.

Cost benefits include:

- No use of live consumables (fuel, water, chemicals)

- No travel or lodging requirements for trainers

- No wear and tear on real equipment

- No disruption of operations during training

- Scalable programs across multiple locations

The result is a more efficient use of resources while expanding access to quality training.

Leveraging Data for Measurable Results

Virtual training platforms provide built-in analytics to track progress, measure performance, and identify trends across teams. Every task completed inside a simulation can be evaluated based on timing, accuracy, compliance, and corrective actions.

This data helps managers:

- Pinpoint areas of misunderstanding

- Validate skill development before certification

- Track employee readiness for specific tasks

- Customize retraining plans

- Generate audit-friendly training reports

The metrics outlined above turn training from a checkbox into a performance-driven process. Instead of guessing who is ready, you know.

Supporting Regulatory Compliance and Audits

Oil and gas companies must comply with strict international, national, and regional safety and training regulations. Being able to prove that personnel are properly trained is essential for maintaining licenses, passing audits, and avoiding fines.

Virtual training systems support compliance by:

- Offering complete records of training activities

- Storing user-specific progress and completion data

- Documenting the exact procedures followed in each simulation

- Demonstrating proactive risk management during evaluations

Training records are centralized, easily retrieved, and tied to each individual, making it easier to meet documentation demands from auditors or partners.

Strengthening a Safety-First Culture

A true safety culture goes beyond rules. It's built through behavior, practice, and reinforcement. Virtual training immerses users in that culture by making safety a lived experience, not just a written policy.

Every time a worker puts on a VR headset, they engage in scenarios where their actions matter. They become used to identifying hazards, communicating with team members, and taking initiative under pressure. Over time, this repeated engagement helps establish habits that carry over into real-world environments.

Conclusion

The oil and gas industry cannot afford uncertainty in training. Safety, reliability, and efficiency depend on people who are prepared technically, physically, and mentally for the conditions they face. Traditional training alone cannot meet this challenge.

Virtual reality training solutions deliver hands-on readiness without risk. They improve onboarding, enable crisis rehearsal, ensure consistency, and generate measurable performance data. From offshore platforms to processing plants, simulation-based learning helps operations run more smoothly, safely, and with greater accountability.

To equip your workforce for the demands of modern energy production, explore how virtual training in technology can become your advantage in safety, compliance, and operational performance.

Found 49 results