Virtual Training in Manufacturing

The manufacturing industry is under continuous pressure to improve productivity, reduce risk, and adapt to automation. Assembly lines, industrial robotics, digital control systems, and multi-step processes define a space where minor errors can lead to significant downtime or safety incidents. Yet training methods often lag behind the complexity of the equipment and environments workers must master.

Virtual training in technology offers manufacturers a way to bridge this gap. Your teams can engage with realistic work scenarios through simulation-based instruction before touching the production floor. Virtual reality training solutions provide a controlled, repeatable environment where workers build hands-on skills, react to safety-critical situations, and gain experience with digital systems that power modern plants.

Where Traditional Training Falls Short

No matter the size or specialization of your facility, workforce development remains a complex problem. Most manufacturers rely on experienced staff to walk new hires through tasks or use manuals and video content to convey procedures. These approaches often result in slow onboarding, skill gaps, and inconsistent knowledge.

Core limitations manufacturers face include:

- Live systems are not always accessible for training during production.

- Human-led instruction varies based on shift, location, or trainer availability.

- Mistakes during learning cause real consequences for safety or throughput.

- Little visibility exists into what a trainee truly understands until something goes wrong.

Virtual training in technology transforms instruction into something repeatable, measurable, and job-specific. It allows you to scale effective learning across your workforce without halting your operation.

Building Skill Depth, Not Just Task Familiarity

In many manufacturing environments, training stops at operational basics. Workers learn to complete a single task, follow a routine, and repeat it without error. But what happens when a deviation occurs? What if a component shifts, a variable changes, or a step is missed?

Simulation-based training helps your team go beyond memorization. It builds a deeper understanding of why processes work, not just how. Through scenario-based challenges, workers learn to diagnose errors, adapt to disruptions, and recognize how their role connects to the larger system.

For example, an assembly line operator may know how to follow a standard wiring process. However, they might be asked to complete the same task in a simulation with a missing part, unusual spacing, or incorrect labeling. Instead of guessing or stopping production, they learn to apply structured problem-solving like in real life. Staff are less likely to panic, escalate minor issues, or fall behind during process changes. As operations evolve, they adapt faster and with fewer mistakes.

With virtual technology training, you develop a workforce that isn't just compliant and capable. Simulation transforms routine operators into thinkers, contributors, and agile problem solvers who actively protect throughput and quality in your manufacturing industry operations.

Aligning Workforce Development With Lean Manufacturing Goals

Manufacturing organizations that embrace lean principles focus on eliminating waste, standardizing processes, and driving continuous improvement. However, these goals are difficult to reach when training is inconsistent or reactive. Simulation-based learning offers a more strategic way to align workforce development with lean priorities.

Virtual training makes standardization possible across every team and site. No matter where an employee is located, they receive the same training delivered in the same way, using the same logic, terminology, and workflow.

It also supports continuous improvement. Performance data collected during each simulation allows trainers to see what steps consistently create slowdowns or errors. They can then adjust content, retrain specific workflows, or share insights with process engineers. Training becomes a real feedback loop, not a fixed curriculum.

Simulation also helps eliminate waste in onboarding. Instead of waiting for live system access, new hires start with hands-on virtual experience. They make mistakes without consuming materials or taking equipment offline. By the time they reach the floor, they are more efficient, accurate, and ready to contribute to lean outcomes.

When you embed virtual reality training solutions into your lean strategy, you're teaching tasks and supporting long-term operational excellence. Eliminating rework, improving first-time quality, and building a culture of high standards across your manufacturing software solutions and plant floor practices becomes easier.

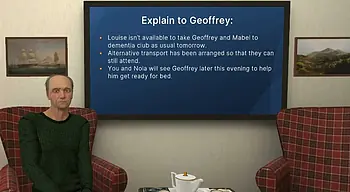

Shifting from Shadowing to Simulation

In manufacturing, hands-on experience matters. But shadowing an experienced operator is rarely efficient. People retain more when they're active participants, not passive observers. That's where simulation training excels.

Virtual programs place each learner inside a digitally recreated version of their work zone. From adjusting machine settings to completing a full process cycle, they engage with lifelike tasks using familiar equipment models and your exact manufacturing software solutions.

Trainees benefit from:

- Learning at their own pace, with guided support and instant feedback

- Making and correcting mistakes without disrupting output or causing damage

- Practicing rare but high-risk events, like machine lockouts or emergency shutdowns

Simulation-based learning also removes pressure. Workers don't have to learn everything during their first week. They can gradually revisit programs, build confidence, and show readiness through tracked progress.

Rehearsing Safety Where It Matters Most

The importance of safety in manufacturing industry settings is impossible to ignore. Slips, chemical exposure, collisions, and machine-related injuries are daily risks. Yet safety drills are hard to execute in active environments, and briefings often become routine checklists.

Immersive training fixes this problem. You can recreate safety-critical incidents in controlled, interactive ways that make an impact. Instead of reading rules, workers actively respond to fires, pressure leaks, or shutdown triggers inside a simulation.

Examples include:

- Practicing correct PPE procedures for specific zones

- Running accident response drills for electrical faults or material spills

- Identifying workplace hazards while navigating a virtual production floor

These exercises build decision-making skills and physical habits. The result is a workforce that treats safety as a lived behavior, not just a compliance checkbox.

Creating Digital Confidence in Software-Driven Plants

Modern factories run on data. Workers interact with ERP systems, SCADA dashboards, and MES platforms daily. But digital tools are often underused, misunderstood, or ignored when staff aren't trained to use them properly.

That's why simulation learning includes more than physical equipment. It can embed your actual interfaces into the learning flow, showing staff how to input data, monitor KPIs, adjust variables, or respond to alerts inside your software systems.

When your team understands the digital side of production, you:

- Prevent process delays caused by data input mistakes

- Improve reporting accuracy from the ground up

- Increase software ROI by encouraging confident system use

The more familiar your team is with your manufacturing software solutions, the more value you get from your automation and analytics investments.

From Observation to Optimization: Data-Driven Training

Every movement, decision, and result inside the simulation is logged. Managers and trainers gain a live view of how well people are progressing and where support is needed.

You can measure:

- How quickly learners complete tasks

- What types of mistakes are common

- How often are safety rules followed or ignored

- When someone is ready for more responsibility

Instead of assuming a worker is ready, you can show it. And if someone needs more time, you'll know precisely what to reinforce.

Adapting to Change Without Interrupting Operations

The manufacturing industry never stands still. New product lines, system upgrades, supply chain shifts, and staffing changes happen constantly. Preparing your teams for each transition is vital, but live training slows you down.

Simulation offers an alternative. You can:

- Launch new workflows inside a virtual model before any line changes are made

- Train staff on updated SOPs while production continues normally

- Introduce new roles or technologies without a lengthy trial-and-error phase

Training becomes part of your change management strategy. Everyone is prepared, and no shift is left behind.

Scaling Without Scaling Your Team

Growth creates strain when training is tied to instructor capacity or in-person meetings. Opening a new facility or onboarding hundreds of seasonal workers can overwhelm your training resources.

Virtual reality training solutions scale differently. Once a program is developed, it can be used by 5 or 5,000 employees anywhere, anytime. There are no extra classrooms, no duplicate sessions, and no delays.

Use simulation to:

- Support expansion plans without training bottlenecks

- Create consistent knowledge across sites and language groups

- Offer refresher programs on demand instead of on a schedule

Such an approach keeps your operations agile. You can respond to labor shifts, project launches, and compliance audits without disrupting throughput.

Making Every Role Training-Ready

The value of simulation reaches every layer of your organization:

- Production workers get confident with tools, processes, and safety rules

- Technicians practice service routines without shutting down machines

- Supervisors identify talent and assign development paths

- Compliance teams access complete training records instantly

- Executives track performance improvement against goals

Choose a Partner That Understands Manufacturing

At Program-Ace, we design immersive training solutions tailored to the manufacturing industry. We combine real-world accuracy with digital precision, building simulations that match your environment, equipment, and goals.

Our team works directly with your subject matter experts to:

- Translate internal procedures into step-by-step simulations

- Digitally model your spaces, stations, and control panels

- Connect training progress to your LMS or compliance systems

Whether you need a single safety solution or a full training library for cross-functional roles, we help you launch faster, train better, and track more accurately.

Future-Proof Your Workforce Now

Modern manufacturing is complex, fast-moving, and software-driven, and training has to evolve with it. Simulation helps your team stay sharp, aligned, and ready without adding risk, delays, or confusion.

Contact Program-Ace and start building training that matches your teams' real challenges. Let's create simulations that prepare people for everything from safety to digital systems to precision workflows, so your operations can grow stronger from the inside out.

Found 49 results