Virtual Simulations in Cross-Industry

Industries today face diverse yet interconnected challenges: safety risks, operational inefficiencies, compliance demands, and the constant need for innovation. Whether in manufacturing, construction, energy, logistics, healthcare, or retail, organizations must balance cost, speed, and accuracy under conditions where errors can be costly.

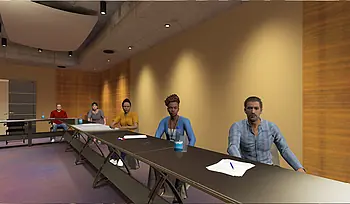

Virtual simulations address this problem by providing a flexible and scalable framework that can adapt to multiple industries. A virtual business simulation provides the same structured benefits, such as risk-free practice, measurable outcomes, and team alignment, regardless of sector.

By creating scenarios that mirror real responsibilities and pressures, virtual simulation helps companies test workflows, evaluate decisions, and train staff without exposing them to real-world risks. Cross-industry adoption enables the transfer of lessons learned in one field to another, thereby accelerating readiness and fostering organizational resilience at scale.

Challenges Faced Across Industries

While every industry has its unique hazards, several recurring challenges appear universally:

- Safety and compliance. Whether handling hazardous materials or interacting with the public, employees must act correctly under pressure.

- Operational complexity. Cross-functional processes often fail due to miscommunication, delays, or siloed planning.

- Limited rehearsal opportunities. Employees rarely have the opportunity to practice rare but critical scenarios before they occur.

- High cost of mistakes. Errors lead to injuries, downtime, lost revenue, or damaged reputation.

- Uneven training delivery. Global organizations struggle to standardize preparation across locations and languages.

Virtual simulations address these gaps by offering repeatable, measurable practice that can be customized for any role, process, or industry.

The Universal Advantages of Virtual Simulations

Across industries, the adoption of virtual simulation provides measurable benefits:

- Risk-free practice. Teams rehearse high-stakes decisions without consequences.

- Consistency. All participants receive identical training and scenarios.

- Measurable outcomes. Every decision, action, and delay is logged for analysis.

- Flexibility. Simulations adapt to unique workflows, systems, or regulations.

- Scalability. Training and process rehearsal can be deployed globally, regardless of geography or time zone.

- Engagement. Interactive scenarios increase retention compared to static documents or lectures.

By applying these benefits universally, organizations strengthen their ability to respond effectively across all business functions.

Industry Applications of Virtual Simulation

Manufacturing and Industrial Operations

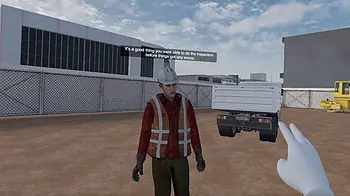

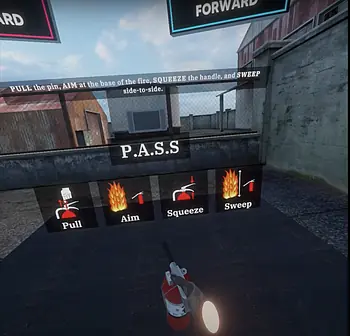

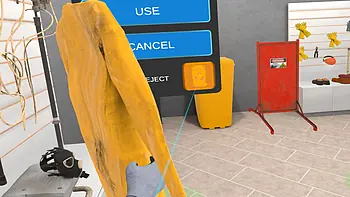

In manufacturing, process optimization and workplace safety are constant priorities. Virtual simulations help employees practice lockout-tagout procedures, rehearse machine operation, and refine assembly workflows. Process engineers use simulation to model production line changes, test material substitutions, or predict bottlenecks before altering live systems.

Construction and Infrastructure

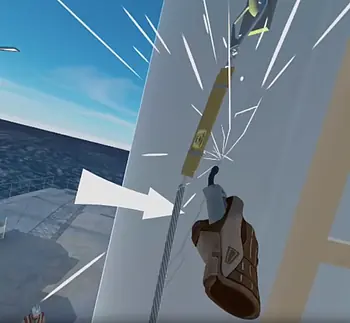

The construction industry faces unique coordination challenges across trades, timelines, and safety protocols. Virtual business simulation allows teams to rehearse crane operations, emergency evacuations, or trade scheduling conflicts. Site-specific hazards such as confined spaces or fall risks are mirrored in digital environments, ensuring preparedness before ground is broken.

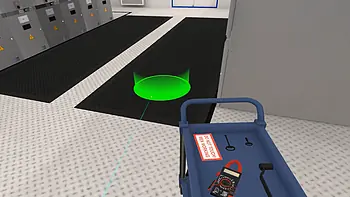

Energy and Utilities

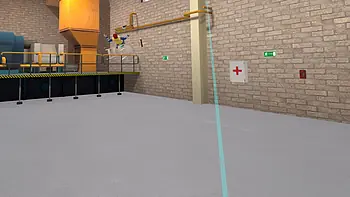

In the energy and utilities sector, operational reliability and safety are paramount. Simulations replicate high-voltage procedures, equipment maintenance, or emergency shutdowns. Digital twins allow operators to test new protocols against live data, ensuring compliance with strict industry regulations while minimizing downtime.

Healthcare and Life Sciences

Healthcare providers use virtual simulation to practice emergency response, surgical procedures, or patient triage. Staff rehearse decision-making in high-pressure environments where seconds matter. Beyond clinical settings, simulations test administrative workflows, compliance requirements, or response to large-scale events like pandemics.

Logistics and Transportation

In logistics, simulations train staff on warehouse operations, supply chain delays, or transportation risks. Teams rehearse procedures for vehicle breakdowns, hazardous material handling, or cross-border regulatory changes. Virtual simulation helps maintain efficiency in complex, global supply chains.

Retail and Service Industries

Retail organizations face challenges in customer service, crisis management, and operational rollouts. Virtual simulations enable employees to practice handling customer escalations, adapting to new systems, or responding to safety incidents in public environments, all in a safe, repeatable framework.

Structuring Simulation Across Industries

While use cases vary, the structure of cross-industry virtual simulations follows a common pattern:

- Scenario definition. Identify a process or situation where rehearsal would reduce risk or increase efficiency.

- Role mapping. Align responsibilities so each participant experiences their tasks realistically.

- Simulation design. Build a digital environment that mirrors workflows, tools, and systems.

- Execution. Participants interact with evolving scenarios that reflect real risks and time constraints.

- Measurement. Collect data on accuracy, timing, communication, and compliance.

- Review and iteration. Adjust scenarios to reflect lessons learned, new regulations, or updated procedures.

Such a structure allows organizations in different industries to apply the same framework while customizing content for their own needs.

Safety Simulation as a Cross-Industry Priority

Safety is a universal concern across industries. Whether managing construction equipment, manufacturing machinery, or healthcare emergencies, employees must respond without hesitation. Virtual safety simulations expose workers to hazardous situations in a safe, controlled environment. Repeated exposure builds confidence, strengthens reflexes, and reduces incidents. Because scenarios are standardized, companies achieve consistent safety readiness across all sites and roles.

Process Optimization Through Simulation

Beyond safety, virtual business simulation strengthens operational performance. By modeling workflows end-to-end, companies can identify bottlenecks, test new methods, and measure the impact of decisions before deploying them in live operations.

Examples include testing new logistics routing strategies, simulating production line reconfigurations, or rehearsing cross-department communication chains. These simulations reveal inefficiencies and allow leaders to make data-driven improvements that reduce costs and delays.

Measuring Performance Across Industries

Traditional training often relies on subjective or inconsistent assessments. Virtual simulations provide measurable, behavior-based data that informs decision-making.

Metrics typically include:

- Time to complete tasks.

- Accuracy of decisions under pressure.

- Adherence to safety or compliance protocols.

- Communication effectiveness between roles.

- Comparative performance across teams or regions.

These insights allow leadership to identify systemic issues, guide retraining, and track progress over time.

Scaling Cross-Industry Training

For global organizations, one of the greatest challenges is delivering consistent training across regions. Virtual simulation resolves this by:

- Allowing simultaneous deployment across multiple geographies.

- Supporting localization for languages and regulations.

- Providing flexible access across shifts and time zones.

- Standardizing reporting for central oversight.

Business Continuity Through Simulation

Disruptions such as supply chain breakdowns, workforce shortages, or system outages affect every industry. Virtual simulations prepare organizations to respond consistently.

By simulating disruptions, companies can observe how teams adapt, how quickly recovery begins, and what gaps must be closed. These lessons strengthen business continuity plans and reduce reliance on reactive measures.

Implementing Cross-Industry Simulation Programs

Adopting cross-industry simulation follows several steps:

- Pilot deployment. Begin with a high-impact process, such as emergency response or equipment safety.

- Content development. Align scenarios with standard procedures, compliance requirements, and real-world workflows.

- Rollout and scaling. Deploy across departments, sites, or industries with remote accessibility.

- Analytics and refinement. Use performance data to identify weaknesses and guide retraining.

- Expansion. Introduce more scenarios, integrate digital twins, and evolve simulations alongside organizational change.

Long-Term Advantages of Cross-Industry Simulation

Adopting simulation across industries provides organizations with enduring benefits:

- Accident reduction. Safety rehearsal lowers incident rates universally.

- Improved efficiency. Operational bottlenecks are identified and corrected.

- Cost savings. Preventing errors reduces downtime and resource waste.

- Faster onboarding. New employees engage with simulations immediately, reducing ramp-up time.

- Innovation adoption. New systems and tools are tested virtually before live deployment.

- Institutional knowledge. Best practices are preserved and standardized across regions and teams.

Cross-industry virtual simulation becomes a long-term asset, embedding readiness into organizational culture.

Building a Culture of Preparedness

The most significant benefit of cross-industry simulation is cultural. Employees learn to expect rehearsal before execution, reducing improvisation and uncertainty. Managers gain visibility into readiness. Leadership sees measurable data that supports decisions.

Therefore, the shared culture of structured preparation transforms how organizations approach challenges. Safety becomes embedded, efficiency improves, and projects run with greater reliability.

Conclusion

Industries differ in function but share common challenges: risk, complexity, and the need for reliable execution. Traditional training and planning tools leave gaps that result in preventable incidents and inefficiencies.

Virtual simulations provide the solution. By creating risk-free, measurable, and scalable environments, they prepare employees, optimize processes, and align organizations across functions and geographies. Virtual business simulation ensures readiness before real-world challenges occur, reducing risk and strengthening performance across industries.

Cross-industry virtual simulations move organizations from assumption to tested action. Regardless of sector, teams gain the opportunity to practice, improve, and execute with confidence.

Found 19 results