Workplace Safety Virtual Simulations

Workplace safety impacts every level of an organization. Regulatory compliance, employee health, and operational continuity all depend on how well safety procedures are understood and applied. Static documents, safety posters, or occasional training sessions rarely prepare personnel for actual risk conditions. A written checklist cannot replicate the urgency of reacting to a fire, handling hazardous materials, or responding to equipment failure.

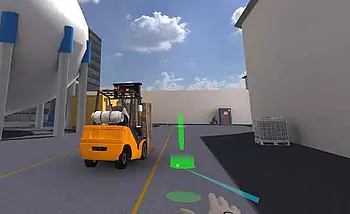

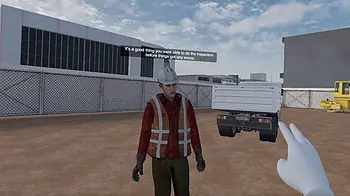

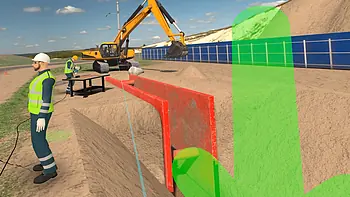

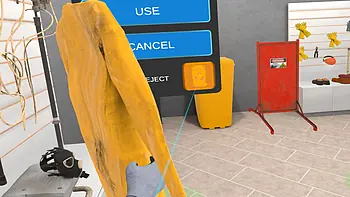

Virtual simulations address this limitation by creating structured, repeatable safety environments. Each workplace safety virtual simulation replicates conditions employees may face, from slips and falls to chemical leaks or confined-space incidents. Participants respond directly to evolving risks, practice decision-making, and experience the consequences of errors without exposing themselves or the company to real danger.

Instead of treating safety as a compliance obligation, organizations gain a system for embedding safe behavior into daily practice.

Common Causes of Workplace Safety Failures

Workplace incidents often stem not from lack of knowledge but from incomplete preparation.

Typical failure points include:

- Information gaps. Safety policies may exist but are not fully communicated across teams.

- Low-frequency training. Infrequent drills leave employees unprepared for sudden hazards.

- Unrealistic exercises. Demonstrations often omit urgency, distractions, or time pressure.

- Poor cross-role alignment. Staff may understand their role but not how their actions affect others.

When emergencies occur, even minor delays in recognizing risks or coordinating responses can escalate into serious injuries or financial losses. Virtual safety simulation provides the missing element: immersive practice under controlled but realistic conditions.

What Workplace Safety Virtual Simulations Deliver

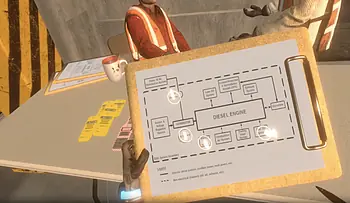

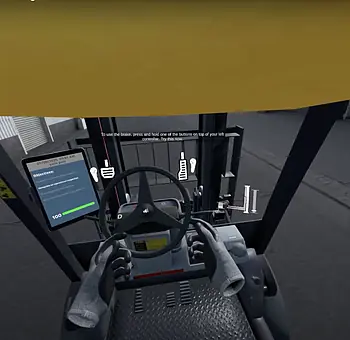

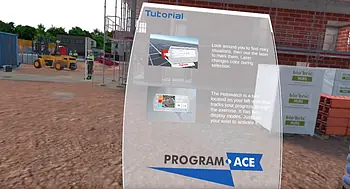

Unlike generic e-learning courses, workplace safety virtual simulations create interactive, evolving scenarios with measurable outcomes. Participants operate in digital replicas of their actual environments, using role-specific procedures and tools.

Key capabilities include:

- Dynamic scenario flow. Hazards escalate or stabilize depending on user actions.

- Role-based logic. Each participant follows tasks aligned with their real responsibilities.

- Immediate feedback. Correct and incorrect actions generate measurable outcomes.

- Data-driven insight. All decisions are logged for review, analysis, and compliance reporting.

By engaging with simulated risks, employees not only learn procedures but also internalize safe decision-making patterns.

Types of Workplace Safety Scenarios

Virtual safety simulations adapt to industries ranging from manufacturing to office operations. Scenarios reflect actual risks employees encounter in their daily environment.

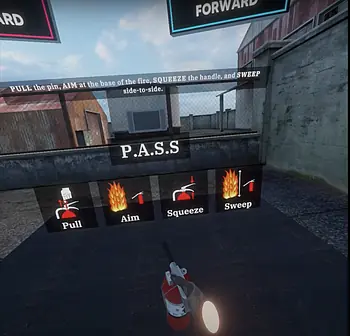

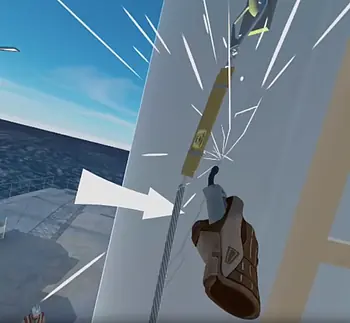

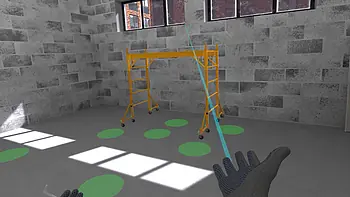

Examples include:

- Machinery lockout-tagout failures and energy release hazards.

- Fire suppression procedures during localized equipment ignition.

- Forklift and heavy-vehicle navigation in shared spaces.

- Hazardous material handling and spill containment.

- Fall prevention during scaffolding or ladder operations.

- Confined space entry with oxygen monitoring requirements.

- Office evacuation under fire or seismic conditions.

Each scenario is configured to replicate local regulations, site layouts, and organizational policies, ensuring the training reflects the real workplace rather than generic risks.

Beyond Compliance: Embedding Safety Culture

Most organizations conduct safety training to meet compliance standards. However, compliance alone does not guarantee safe behavior in practice. Employees must be able to recognize, react, and coordinate under pressure.

Virtual simulations bridge the gap between documented compliance and lived behavior. By practicing in a controlled setting, personnel gain familiarity with:

- Identifying early indicators of hazards.

- Prioritizing actions under time pressure.

- Coordinating responses with colleagues.

- Applying procedures consistently across shifts and sites.

The result is not only compliance but also a culture of proactive safety, where employees understand why procedures exist and how they prevent harm.

Virtual Simulation vs. Traditional Safety Drills

Traditional drills often face limitations:

| Drill-Based Training | Virtual Safety Simulation |

| Conducted infrequently | Accessible on-demand and repeatable |

| Limited to specific locations | Scalable across sites and regions |

| Difficult to measure performance | Every action tracked and analyzed |

| Often generic and role-agnostic | Customized to roles, tasks, and risks |

Virtual workplace safety simulations extend preparation beyond one-off sessions, allowing every employee to rehearse safety-critical scenarios as often as necessary.

Structuring Decision-Making Under Stress

Safety incidents rarely occur in controlled environments. Instead, they arise amid distractions, incomplete data, and competing priorities. Virtual simulations are intentionally structured to replicate such conditions.

Participants face:

- Conflicting cues that require prioritization.

- Time-sensitive decision points with measurable consequences.

- Partial information that demands judgment.

- External dependencies, such as waiting for supervisor clearance or equipment readiness.

By replicating these constraints, simulations reveal gaps in response chains and highlight areas requiring additional training.

Benefits of Workplace Safety Virtual Simulations

Adopting simulation platforms creates measurable advantages across organizations:

- Consistent preparation. All employees experience the same scenarios, regardless of location or schedule.

- Improved retention. Repetition under realistic conditions reinforces long-term memory of safety procedures.

- Cross-functional alignment. Teams see how their actions affect others' safety.

- Reduced incident frequency. Employees recognize hazards faster and act more decisively.

- Cost savings. Fewer real-world accidents reduce medical, legal, and operational expenses.

- Audit readiness. Recorded simulation results provide verifiable compliance evidence.

Simulation turns safety from a reactive process into a proactive system.

Measuring Readiness Through Simulation

Traditional assessments rely on quizzes or self-reports, which rarely reflect real behavior under stress. Virtual simulations capture factual performance data, including:

- Decision accuracy. Whether users selected the correct procedures.

- Response time. How quickly actions were taken after an event occurred.

- Coordination metrics. How effectively individuals communicated or escalated.

- Completion rates. Which employees have rehearsed required scenarios.

Reports provide leadership with concrete insight into safety readiness across teams, departments, or facilities. Gaps become visible, measurable, and addressable.

Scaling Safety Training Across Locations

Global organizations often struggle to deliver consistent safety training across distributed sites. Variations in instructors, languages, or schedules create uneven results.

Virtual workplace safety simulations eliminate these barriers. Once created, scenarios are accessible online for any division or facility. Benefits include:

- Remote deployment. Training is available regardless of geography.

- Localized content. Simulations support translation and site-specific assets.

- Flexible scheduling. Employees complete training without disrupting operations.

- Standardized measurement. All results are recorded in the same format for comparison.

Large-scale readiness becomes achievable without excessive logistics.

Supporting Continuous Improvement

Workplace risks evolve as new equipment, processes, or facilities are introduced. Static manuals often lag behind such changes, leaving employees underprepared.

Virtual simulations adapt rapidly:

- Scenario modularity. Individual hazards or processes can be updated without full redesign.

- Role management. New job functions are integrated into existing simulations.

- Conditional branching. Simulations reflect alternate outcomes based on site-specific risks.

- Environment modeling. Updated floor plans, equipment, or safety systems can be added.

Continuous adaptation ensures that safety training evolves in tandem with the workplace.

Integration with Broader Safety Programs

Workplace safety does not exist in isolation. It intersects with compliance, HR onboarding, and operational planning. Virtual simulations integrate smoothly with these initiatives by:

- Serving as part of the onboarding for new employees.

- Linking results to HR systems for performance tracking.

- Supporting occupational health and safety (OHS) audits.

- Aligning with broader business continuity plans.

Simulation becomes not just a training tool but a central element of organizational resilience.

Reducing Support Load and Escalations

When employees are unprepared, even minor safety incidents can escalate, requiring intervention from supervisors or external responders. Virtual simulations reduce this burden.

Employees who have rehearsed scenarios recognize risks earlier, act independently, and avoid unnecessary escalation. Support teams benefit from a shared understanding of procedures, reducing the time required to resolve incidents. Over time, organizations see measurable reductions in safety-related downtime and resource strain.

Building a Culture of Preventive Safety

Workplace safety virtual simulations extend beyond individual exercises. By engaging employees repeatedly with realistic scenarios, organizations foster a preventive safety culture. Characteristics of such a culture include:

- Employees proactively identify and report hazards.

- Teams are coordinating responses without hesitation.

- Managers are gaining transparent insight into systemic weaknesses.

- Safety is becoming embedded into daily routines, not treated as an exception.

Organizations with a preventive culture see fewer accidents, greater compliance, and stronger employee confidence.

Adapting to Regulatory and Industry Standards

Different industries face unique compliance demands, from OSHA standards in the U.S. to EU workplace directives. Virtual simulations help demonstrate adherence by:

Providing documented participation logs. Linking simulation content to specific regulatory requirements. Offering version control for updated policies. Supplying auditors with evidence of structured training.Instead of relying on paper checklists, organizations show verifiable proof of employee preparation.

The Enhancement of Long-Term Organizational Resilience

Workplace safety is not a one-time initiative. Over the years, organizations evolve, risks change, and staff turnover introduces new variables. Virtual simulations ensure continuity by preserving institutional safety knowledge.

New hires engage with the same structured scenarios as experienced employees. Managers evaluate readiness consistently across generations of staff. Leadership gains the ability to track improvements, benchmark readiness, and implement corrective actions. Safety stops being episodic and becomes a permanent, measurable strength.

Conclusion

Workplace safety depends on preparation, alignment, and repeated practice. Paper-based policies and occasional drills cannot provide the consistency required to prevent injuries and safeguard operations.

Workplace safety virtual simulations create interactive, scalable, and measurable environments where employees practice risk recognition, response, and coordination under realistic conditions. Every action is logged, every decision is tested, and every team gains clarity on their responsibilities.

Organizations reduce accidents, save costs, and build confidence. Employees gain familiarity with hazards before encountering them in practice. Leadership receives measurable data instead of assumptions.

Safety performance improves not by chance but by structured simulation. Workplace safety virtual simulations transform compliance requirements into a system of continuous readiness and resilience.

Found 31 results