In this VR simulator, participants learn to select the correct slinging method based on the work permit's detailed guidelines, which include the load's weight, dimensions, and the sling's load capacity—options vary between textile and iron. The training involves choosing the appropriate sling and then safely transporting the load to a designated location.

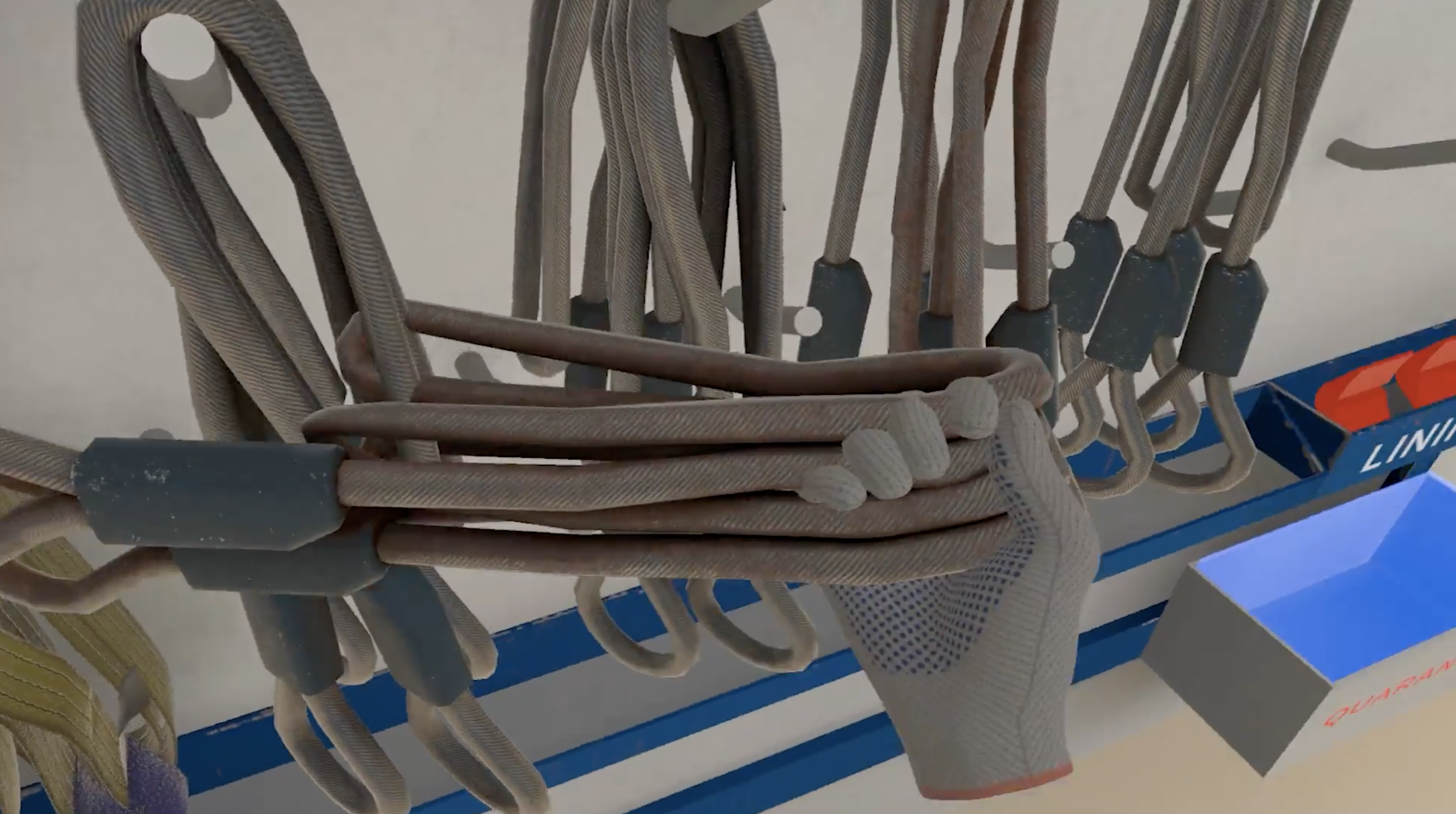

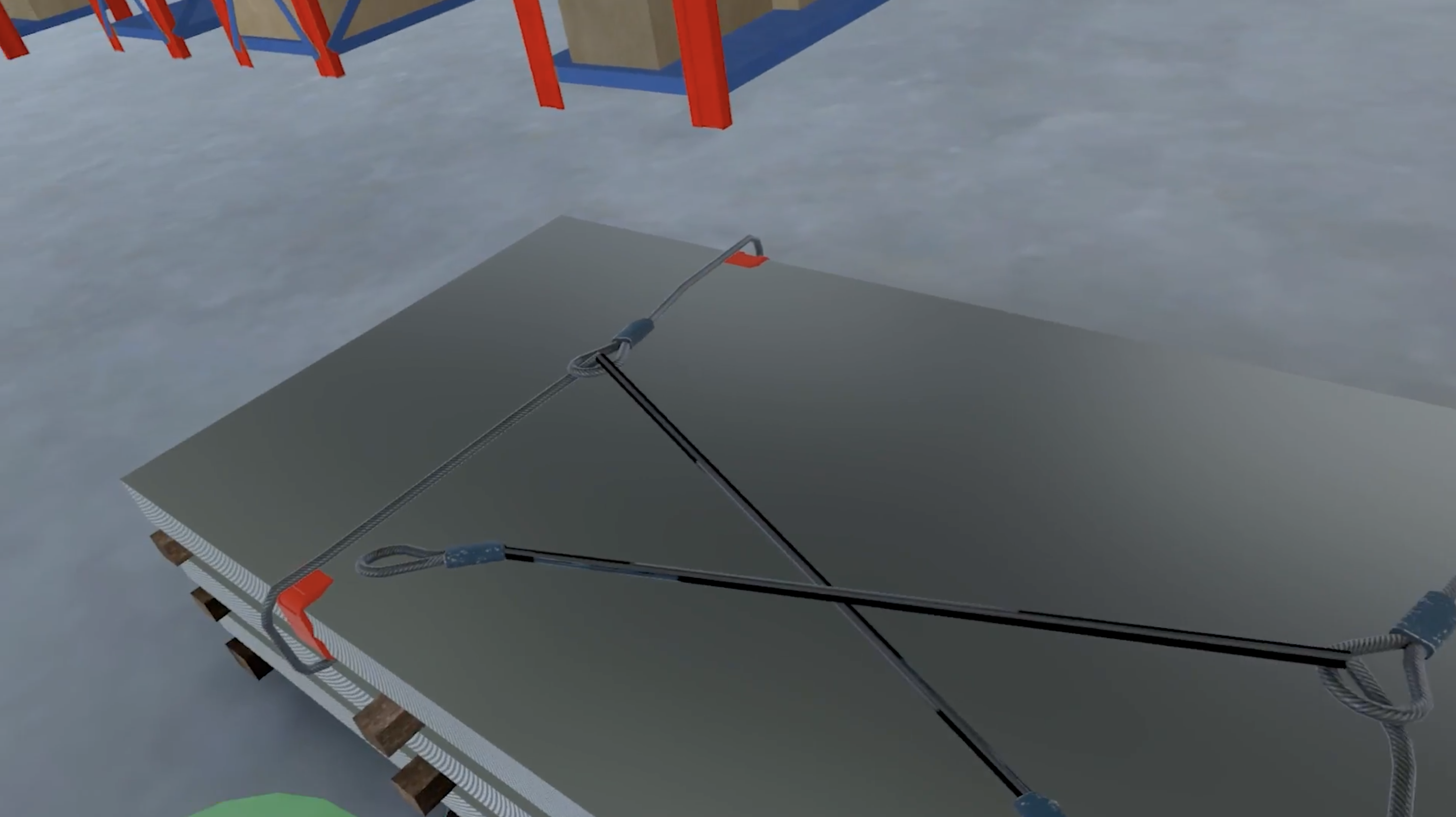

Through this VR simulator, participants master the selection of suitable slinging types based on process routing, considering the load's weight, dimensions, and sling capacity (textile or iron). The training covers proper sling hooking, wrapping, and installation techniques, followed by an initial lift to 200-300mm for safe testing and spontaneous load lowering. Trainees then control the load's movement remotely within a hangar. The program adheres to NEBOSH, ISO 45001, and IOGP Operating Management System standards for oil and gas industry safety.

The VR Experience

In this VR experience set in a vast industrial storage facility, participants begin by reviewing and understanding a work permit that details the specific slinging methods required for the task. The next phase involves setting up warning signs and securing the area with tape. Users then identify and segregate damaged tools, placing them in a designated box, while selecting the appropriate tools for the task. Subsequent steps include inspecting the cat-head hook, executing a detailed slinging process, and finally, maneuvering a large pack of metal sheets to a specified location.

English, Arabic, Czech, Dutch, French, German, Italian, Japanese, Korean, Latvian, Mandarin, Persian, Polish, Portuguese, Slovak, Spanish, Swedish, Turkish, Vietnamese

VR

N/A

Video, 3D, Text

HTC Vive Focus 3, Htc Vive Pro, HTC Vive XR Elite, Lenovo VRX, Meta Quest 2, Meta Quest 3, Meta Quest Pro, Pico Neo 3, Pico Neo 4, Pico Neo Pro

Training, VR

GWPro